Capabilities

Assembly

Carburetor assembly, solenoid valve assembly, electronic fuel injector assembly, chain oiler assembly, solenoid oil pump assembly, and more.

Wire Harness

Fully automatic cutting & crimping, uni/multi stripping, resistance welding, soldering, guided terminal insertion, low pressure molding, end of line testing, and more.

Engineered Textiles

Cutting, computerized pattern sewing, lock stitching with thread trimming.

PCBA

Laser marking, solder paste printing, pick and place, reflow soldering, SMT AOI, THT components insertion, wave soldering, THT AOI, depaneling, potting, end of line testing.

Die-Casting

Clamping force: 140 t & 340 t

Plunger diameter: 40-50 mm

Injection weight: 700-1,100 g

Max. casting area: 350 cm2

Plastic Injection

Clamping force: 30-180 t

Injection weight: 193 g

Max. injection area: 201 cm2

Stamping

Capability: 10-80 t

Stroke length: 150 mm

Die height: 330 mm

Slide area: 560×460 mm

Machining

Max stroke: X: 710 mm

Max stroke: Y: 400 mm

Max stroke: Z: 430 mm

Table size: 800×400 mm

Precision: 0.01 mm

Lathing

Max. length: 800 mm

Max. diameter: 38 mm

Precision: ±0.005 mm

Grinding

Distance between centers: 650 mm

Max. Swing (diameter): 350 mm

Machinable OD tolerance: ±0.0015 mm

Machinable roundness: <0.001 mm

Thread Rolling

Max. module: 1.3 mm

Max. out diameter: 40 mm

Max. clamp length: 800 mm

Precision: ±0.03 mm

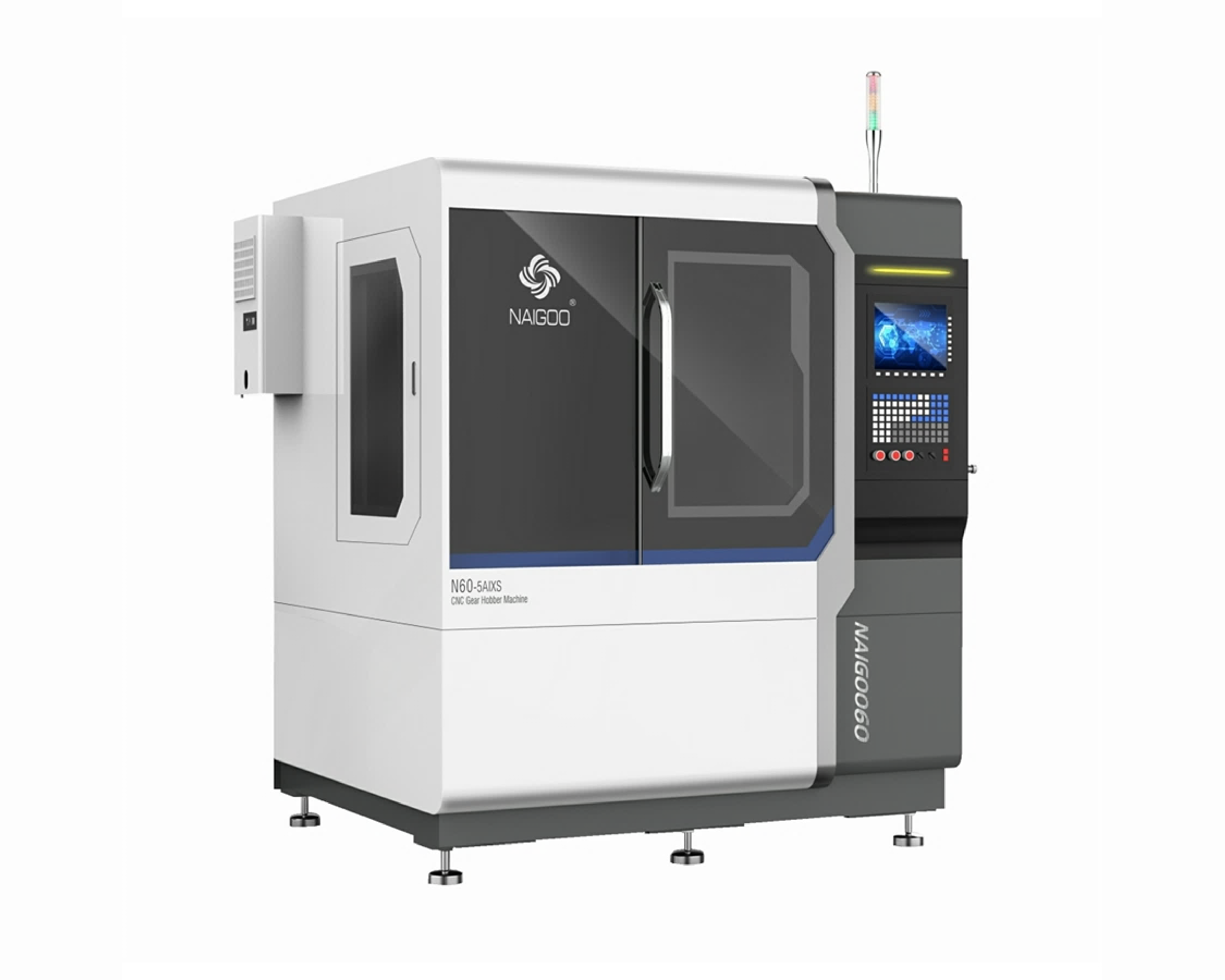

Gear Hobbing

Max. module: 2.0

Process tooth range: 3-999Z

Max. diameter: 120 mm

Max. length: 180 mm

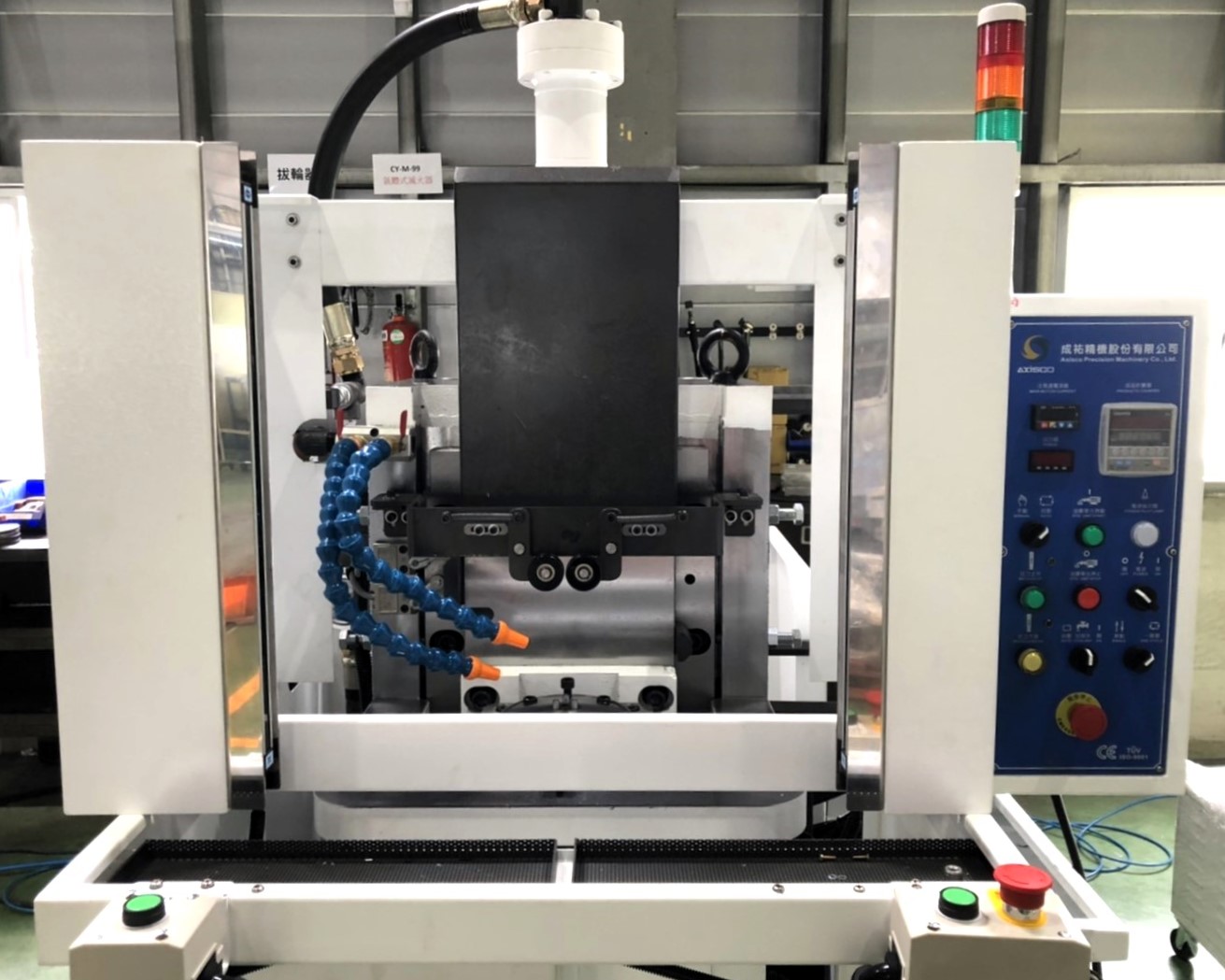

Broaching

Broaching force: 3 t

Max. stroke: 600 mm

Max. aperture: 40 mm

Max. outer diameter: 300 mm

Quality Management

All ZAMA factories are ISO 9001, 14001, 45001 certified. High level of automation with real-time measurements and process traceability allows efficient and reliable quality control.

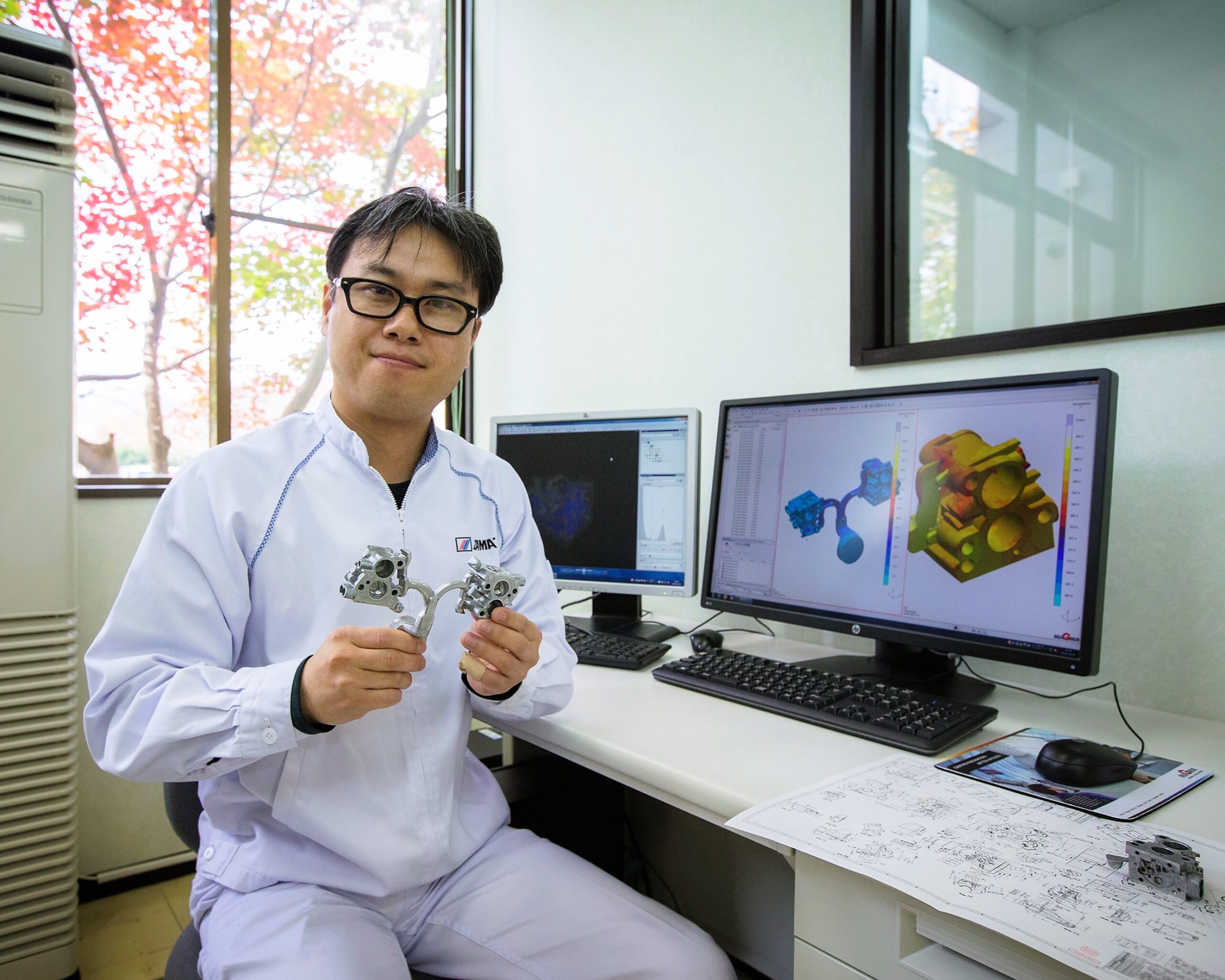

Product Development

ZAMA continuously updates itself to the latest R&D technologies. ANSYS and CFD simulation system are standard tools in our process, completed with testing facilities.

Program Management

As a single point of contact ZAMA program management drives all stages, from ideation to validation into production, providing prompt feedback to customer’s questions.

Innovation

ZAMA innovation is fuelled by collaboration. Constantly developing new solutions that simplify complex systems and accelerate our customers success.